رسالة على الانترنت

رسالة على الانترنت

المزيد من المعلومات

المزيد من المعلومات

2016year9month17day This study presents the effect of ball milling on size and stability of aqueous dispersions of latex compounding ingredients such as china clay, zinc diethyldithiocarbamate, zinc 2-mercapto benzothiazole and butylated reaction product of p-cresol and dicyclopentadiene

Read More

2016year9month17day This study presents the effect of ball milling on size and stability of aqueous dispersions of latex compounding ingredients such as china clay, zinc diethyldithiocarbamate, zinc 2-mercapto...

Read More

Ball mill treatment improved the dispersion of attapulgite in natural rubber composites as indicated by smoother fracture surfaces and resulted in higher tensile strength and crosslink...

Read More

Milling constraints include time duration of milling, ball size, the ball-to-sample content proportion, rotation speed, and energy that took part in a vital part of the structure-property ...

Read More

Ball milling is widely used for preparing filler dispersion for latex compounding ingredients. Ball milling is a mechanical method to reduce crystalline region and modify physicochemical

Read More

2016year1month1day Ball milling method was tailored to improve the ATP dispersion before compounded with latex. The aim of this paper is to investigate the effect of ball milling

Read More

2019year9month12day This study aims to improve the dispersion of treated calcium carbonate (CaCO3) in natural rubber latex (NRL) films. Ball mill and ultrasonic methods were used to break down

Read More

[1]. Ball milling is a technique used for particle size reduction and can also be used for preparing dispersions and for mixing of materials. The grinding or milling pro-cess is accompanied by the

Read More

EFFECT OF COMBINATION ULTRASONIC AND BALL MILLING TECHNIQUES OF FILLERS DISPERSION ON MECHANICAL AND PHYSICAL PROPERTIES OF NATURAL RUBBER

Read More

The success of a ball milling application depends on the correct selection of accessories and process parameters. This includes jar sizes, jar materials, ball sizes, number of balls, particle

Read More

2017year2month13day The apparent difference in capacities between grinding mills (listed as being the same size) is due to the fact that there is no uniform method of designating the size of a mill, for example: a 5′ x 5′ Ball Mill has a working

Read More

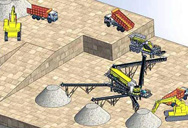

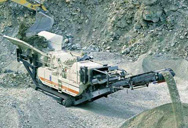

Ball mills are horizontal rotating cylindrical or conical steel chambers, approximately one third to half full of steel, alloy steel or iron balls, like that shown in Fig. 4.10 A–C, or flint stones. The size reduction is accomplished by the impact of these balls on the material as they fall back after being lifted by the rotating chamber.

Read More

Top Glove Business Case Study: Manufacturing Processes. Latex storage- This is the place to store latex that use to produce latex gloves. It place near to the dipping line and chemical dispensing compounding ball mills because it easy for mixing work which need to combine other raw material and chemical substances with latex to produce the latex gloves.

Read More

Compounding is a dispersion process which is done using a dispersion mill Ball mills attrition mills stirrers etc. 2. Compound Mixer. D1076-02 Standard Specification for Rubber - Concentrated, Ammonia It does not apply to natural latex sources other than Hevea brasiliensis nor to compounded latex of a specified dimension.For example, oxide-dispersion

Read More

You can not select more than 25 topics Topics must start with a letter or number, can include dashes ('-') and can be up to 35 characters long.

Read More

Top Glove Business Case Study: Manufacturing Processes. Latex storage- This is the place to store latex that use to produce latex gloves. It place near to the dipping line and chemical dispensing compounding ball mills because it easy for mixing work which need to combine other raw material and chemical substances with latex to produce the latex gloves.

Read More

Ball mills are furthermore characterized by significant differences in the sizes of available grinding jars. Retsch offers mills with jar capacities from 1.5 ml up to 150 l and balls are available from 0.1 mm to 40 mm, see Figure 2. A third and very important characteristic of a ball mill, ...

Read More

Ball Mill For Latex Pounding. Ball Mill For Latex Pounding The rolls and refeeding it into the nip until all the ingredients are added. Mills are used not only for blending of compound open mill mixing but also warming of premixed compound known as warming or cracker m ills, or for cooling compound mixed in an internal mixer known as dump mills.

Read More

Specifications for centrifuged are set or out in creamed, ISO 2004. ISO ISO 2004 deals with three types of centrifuged latex (HA, LA and MA) and two types of creamed latex (HA and LA). ISO 2027 covers three types of evaporated latex [14]. proteins When ammonia and lipid materials are is added for preserving latex, hydrolysed the slowly

Read More

Ball milling is widely used for preparing filler dispersion for latex compounding ingredients. Ball milling is a mechanical method to reduce crystalline region and modify physicochemical properties of starch using friction, impingement, ... Ball mill diameter (mm) Speed (rpm) t us (min) Power (W) Frequency (kHz) Ball milling 90 10 20 300 25

Read More

31/08/2013 ball mill for latex compounding specifications , ball mill for latex compounding specifi ions ball mill machines which type of ball are used in grinder with size Live Chat Ball MillWet Type Ball MillGrinding millBall Grinder Compound Fertilizer Line , and different specifications of steel balls which are loaded , is the whole grinding procedure of ball mill Ball Mill For Latex ...

Read More

Laboratory ball mills have been an essential tool in pharmaceutical research and development for quite some time. These versatile instruments play a pivotal role in the grinding, blending, and homogenization of various materials, offering scientists and engineers the means to explore new formulations and optimize processes.

Read More

The first step in the manufacturing process of rubber mill liners is rubber compounding. This involves the mixing of various raw materials, ... Natural rubber is derived from the latex of rubber trees and is known for its excellent wear resistance and flexibility. ... As a ball mills supplier with 22 years of experience in the grinding ...

Read More

Ball mills are available in various sizes and capacities, and their technical specifications can vary depending on the manufacturer and model. Some of the key technical specifications include: - Diameter and Length: Ball mills are typically available in diameters ranging from 0.6 meters to 4 meters and lengths ranging from 1.5 meters to 12 meters.

Read More

Shera Mathew and Siby Varghese: Natural Rubber Latex-based Nanocomposites with Layered Silicates 5 ( = 0.1542 nm). The samples were scanned in step mode by 1.5º/min scan rate in the range of

Read More

2020year7month13day This document provides an overview of latex ingredients and compounding formulations for latex products. It discusses the key components of natural rubber latex and synthetic lattices like SBR, ... ( P B W ) Zinc oxide 100 - Dispersing agent 2 - Water 98 ; Ball mill for 24 hours. COMPOUNDING INGREDIENTS 11. ACCELERATORS : ...

Read More

If a ball mill uses little or no water during grinding, it is a ‘dry’ mill. If a ball mill uses water during grinding, it is a ‘wet’ mill. A typical ball mill will have a drum length that is 1 or 1.5 times the drum diameter. Ball mills with a drum length to diameter ratio greater than

Read More

2013year8month3day In Grinding, selecting (calculate) the correct or optimum ball size that allows for the best and optimum/ideal or target grind size to be achieved by your ball mill is an important thing for a Mineral Processing Engineer AKA Metallurgist to do. Often, the ball used in ball mills is oversize “just in case”. Well, this safety factor can cost you much in recovery and/or mill liner

Read More

ball mill for latex compounding. ball mill for latex compounding. Function Of Ball Mill In The Latex Compounding. Latex is even being used to help stabilize desert soils to make them suitable for agricultural usesatural latex is produced from the hevea brasilienesis rubber tree and is the protective fluid contained beneath the barkt

Read More

Specification of high energy ball mill: • Principle: Milling to be done using friction and repeated impact of shots and balls. • Applications: Mechanical alloying, homogenization, size reduction, colloidal grinding. These application are the domain of chemistry, civil engineering, recycling of wastes, metallurgy, mining, chemicals, ceramics, and oxides etc.

Read More

المزيد من المعلومات

المزيد من المعلومات

حقوق حقوق التأليف والنشر: رقم التدوين Development Buide 10200540 -22. خط الخدمة: 0371-86549132. E-mail:[email protected] العنوان: الرقم البريدي رقم 169 Second Avenue Avenue New Avenue: Chengzhou الصين: إحصاءات الموقع الشبكي 450001.